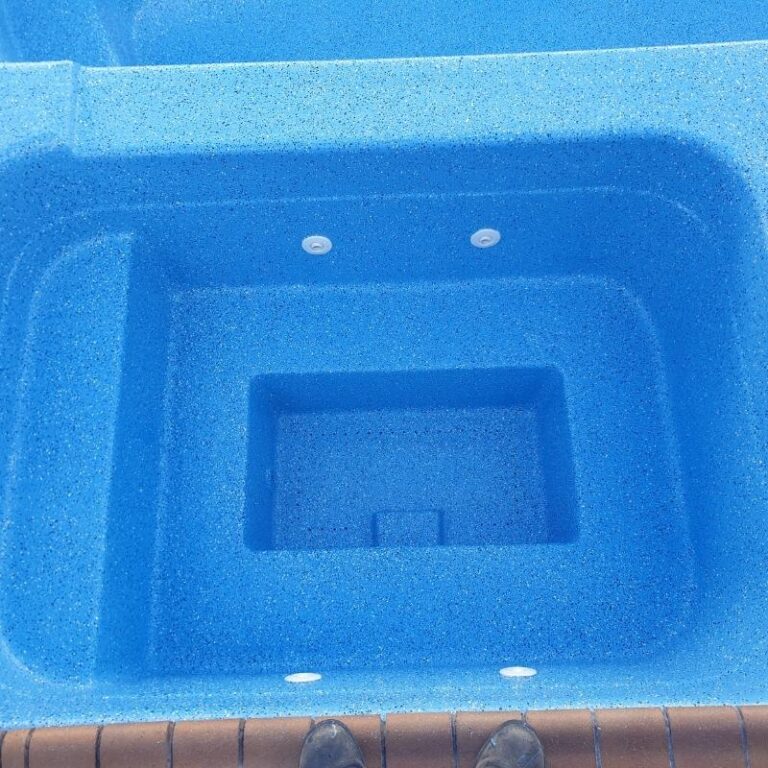

Over time, wear and tear may cause your pool walls to show signs of fatigue and chipping.

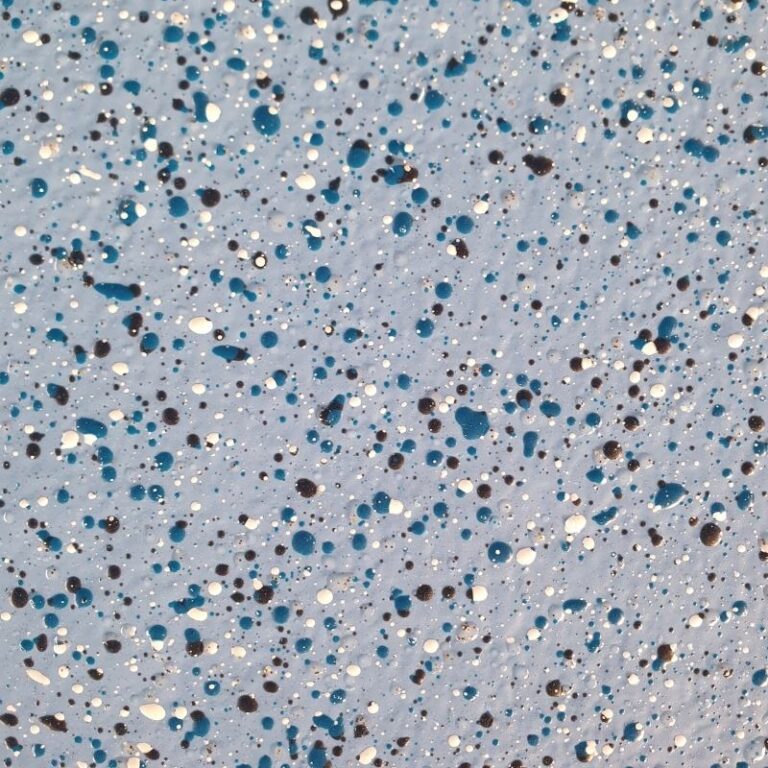

We specialise in fibreglass pool renovations in Griffith and surrounding areas. We can renovate and resurface your entire pool shell.

t’s our recommended and most cost-effective method for restoration, offering substantial savings compared to installing a new pool.